GSE Industrial Design: GSatSolar Part 5, Materials

Series Overview

This industrial design series is a great opportunity for us to show off the design processes we go through at GSE when we're creating new hardware products. This is the penultimate article in a six part series that points the spotlight at our new low-cost tracking terminal, the GSatSolar. If you have not read the other articles in this series, I suggest starting with the introduction piece by clicking here, because it has important information about our processes that will be referenced throughout this article.

Part 5: Materials

Materials selection for the GSatSolar may not seem to be a big deal, but the selection process involved consideration of a number of the product's overall design parameters. Those included the low cost, durability, small size, and animal welfare pillars of our solution. In consideration of all of these factors, our team was fitted with a sizeable and important task of finding the best materials that would result in the greatest performance.

The material selection process included a variety of technical specifications as well, such as dielectric constant and loss tangent, which affect the signal propagation and signal absorption based on the selected material. The highest spec materials for RF are often considered specialty or engineering grade materials, which require special molding processes and temperatures. Another large environmental factor is outdoor suitability based on UL746C, which ideally would meet an F1 rating, indicating it has ideal characteristics for both UV and water immersion tests.

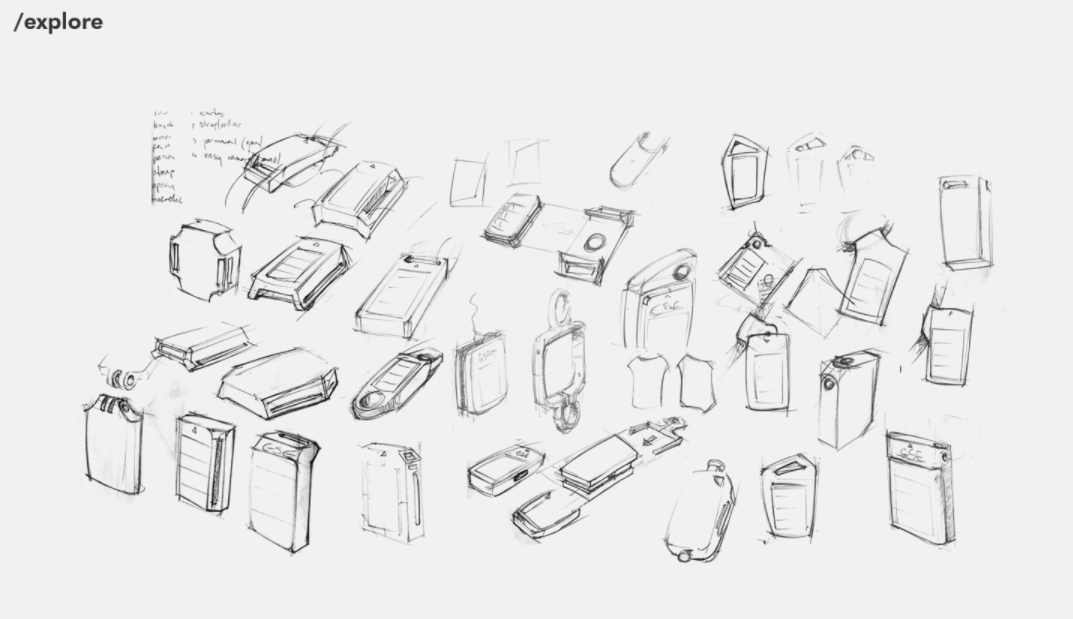

The Design Process

Materials selection is an arduous process for companies that don't have the level of experience and expertise GSE possesses. Knowing how to define requirements, narrow down the catalogues worth of options, and understand how to manipulate the materials to suit the project is a master-class level of expertise that represents a major competitive advantage for firms that have it. In selecting materials for the GSatSolar, GSE employed this expertise to quickly and effectively move from a set of requirements to a perfected proprietary blend.

The Goal

The materials for the components of the GSatSolar and its mounting mechanisms must satisfy a number of different types of functional requirements. First and foremost, the materials must be durable enough to support the most vulnerable parts of the device (like the strap mount bars, for example) while also being lightweight. They must also be non-toxic and ideally medical-grade in order to be conscious of animal welfare. Aesthetically speaking, the terminal has a rugged but sleek appearance that the plastics would need to support, along with coloring and laser engraving. Finally, cost of materials is important because of the GSatSolar design goal of delivering an inexpensive tracking solution.

The Ideas

The availability of plastics and the inundatingly large selection of available materials can be paralyzing to people who don't have expertise in materials selection. Fortunately for us, we have a history of materials expertise, and our industrial designer can likewise navigate the options gracefully. We were able to quickly identify the types of plastics that would meet our requirements so that we could score them accordingly and pick the ones that most adequately satisfied our goals.

Narrowing Down

When we were prioritizing materials, we chose to focus our efforts on the narrowest requirement, which was animal welfare. Narrowing plastics down to a pool that were medical grade and safe for animals helped us rank the remaining options according to durability (which, with medical grade, is typically high), weight, and cost. We knew that aesthetically speaking, we would be able to modify any material in process to meet our needs.

Flesh Out

From our narrowed list of medical grade plastics, we set minimum benchmark levels for durability at varying levels of precision, allowing us to further rank the available options and sort them into tiers of acceptability. From there, we assessed the other factors, moving from the most desirable tiers through the minimum acceptability. What we found through this process was that per unit cost of materials would be relatively similar across all options, and we were able to eliminate that factor from consideration and focus purely on the quality of the materials from a functional performance perspective.

Eliminate

Using the benchmarking criteria outlined above, we were able to select 3 different options that would all be great options for the component pieces of the GSatSolar. We decided to rank them according to their overall performance score, and then go through product testing one-by-one instead of all at once. Our rationalization was that the first choice would be the best choice if it worked, and that we would only need the other two options in the event that the first didn't work. With our backup options in place, we moved to test production with the first material to see if it would support the aesthetic demands of the product.

Iterate

Iteration of GSatSolar materials decisions involved mostly coloration and making sure that the face of the unit could be marked with logo and product information. One design factor for GSatSolar is to be able to be deployed for up to 3 years in harsh outdoor environments. This means that small decisions like coloration would be a larger factor than normal, as white materials absorb less heat when in the sun for prolonged periods of time.

Finalize

To satisfy the coloring needs of the plastic, we identified an additive that would result in a white colored plastic without affecting the strength or animal safety of the material. The added material resulted in an increase of fractions of a penny over hundreds of units, falling again in line with nearly every design requirement of the GSatSolar. With materials selection locked up from a theoretical perspective, the product was ready for some injection mold testing.

The Outcome

Our first run of production mold testing resulted in some complications because of the precision of certain pieces. Our industrial designer met with our production partner to exact the source of the problem, make adjustments to the injection mold process, and solve the problems in less than 24 hours. Production-test GSatSolar cases began rolling out of the factory in early February, and we were able to begin alpha testing of durability, sealing, and mounting shortly thereafter with a handful of future customers.

The GSatSolar is exiting the alpha test phase with incredibly promising results. From the feedback we receive from our testing partners, we will be able to make any necessary adjustments and move into beta testing live, functional units as early as mid-March. It is our goal, pending successful beta test phases and on-schedule factory timelines, to begin delivering functioning units to customers as early as April 2021, bringing a new technology to an industry starving for innovation.

More Information

As mentioned previously, there will be one final article in this series that will bring you through our entire design process for the GSatSolar, with a focus on the major inflection points in the product's history. We encourage you to keep an eye on the blog and our social media as we bring you those articles. For more information about the GSatSolar, we invite you to read more about specs, features, and applications on the product's official website, and sign up for the newsletter as well.